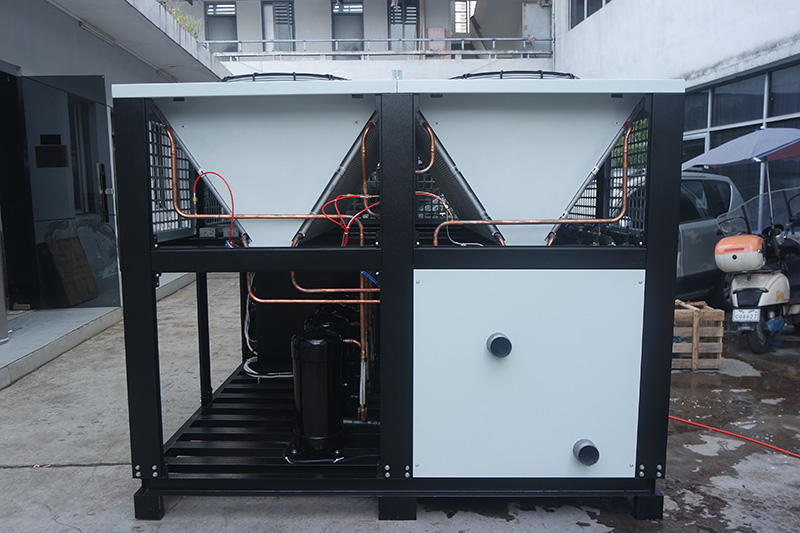

What Is a Screw-Type Air-Cooled Chiller? Screw-type air-cooled chillers are high-performance cooling systems engineered around advanced screw compressors. They leverage air-cooling technology to achieve efficient heat exchange and precise temperature regulation, eliminating the need for complex water-cooling infrastructure. With a cooling capacity range of 10–200 tons, these units are designed to meet diverse industrial and commercial cooling demands

What Is a Screw-Type Air-Cooled Chiller Used For?

These chillers are primarily used to maintain stable temperature levels in critical environments: Industrial settings: Cool machinery, production lines, and equipment to ensure consistent operational performance. Commercial spaces: Regulate temperatures in large-scale buildings (shopping malls, offices, hotels) for optimal comfort.

What Are the Key Advantages of Screw-Type Air-Cooled Chillers?

1.Cost efficiency: Removes the need for water-cooling systems, reducing installation costs. Intelligent controls optimize energy use, lowering long-term operational expenses.

2.High performance: Delivers precise temperature control across 10–200 tons, adapting to varying cooling loads.

3.Durability: Built with rugged components to withstand harsh industrial environments, minimizing downtime.

4.Low maintenance: Designed for easy upkeep, with accessible parts that reduce service complexity.

5.Quiet operation: Operates at low noise levels, suitable for both industrial workshops and noise-sensitive commercial areas.

What Industries Use Screw-Type Air-Cooled Chillers?

1.Plastic industry: Cools injection molding machines and extruders to ensure product quality and precision.

2.Chemical industry: Maintains stable temperatures for chemical reactions, storage, and processing equipment.

3.Pharmaceutical industry: Supports cold chain integrity in drug manufacturing, storage, and production equipment cooling.

4.Large facilities: Ideal for industrial plants, data centers, and commercial buildings requiring reliable cooling.

How to Choose the Right Screw-Type Air-Cooled Chiller?

1.Capacity matching: Calculate your cooling load (consider space size, equipment heat output, and future expansion) to select a 10–200 ton unit that avoids under/over-sizing.

2.Energy efficiency: Prioritize models with high-efficiency ratings and smart control systems to reduce energy consumption.

3.Noise considerations: Opt for low-noise units if installed near offices, residential areas, or quiet workspaces.

4.Maintenance access: Choose units with easily accessible components to simplify regular upkeep.

5.Brand reliability: Select reputable brands with strong after-sales support, ensuring access to technical assistance and spare parts.